- Home

-

Product Center

AS/RS-Stacker Crane

AS/RS-Stacker Crane

AS/RS -Stacker Crane (Pallet Lifter)

AS/RS -Stacker Crane (Double Deep )

AS/RS -Stacker Crane

AS/RS - Pallet Conveyor

AS/RS -RGV

AS/RS -CTV

AS/RS -Pallet Lifter

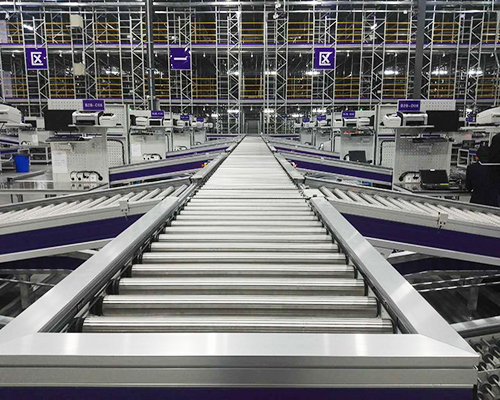

Bin Conveyer System-Aluminum alloy structure series

Bin Conveyer System-Aluminum alloy structure series

Bin Conveyer System-Aluminum alloy structure series

Bin Conveyer System-Aluminum alloy structure series

Bin Conveyer System-Aluminum alloy structure series

Bin Conveyer System-Aluminum alloy structure series

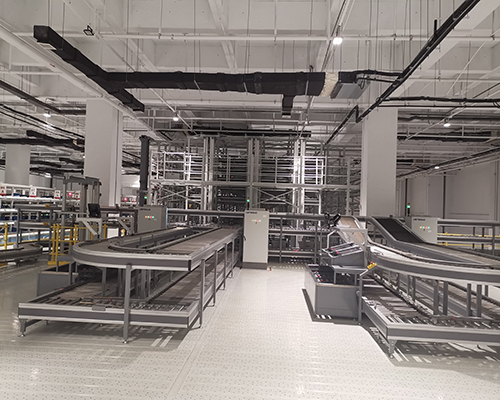

Bin Conveyer System-Carbon steel structure series

Bin Conveyer System-Carbon steel structure series

Bin Conveyer System-Carbon steel structure series

Bin Conveyer System-Carbon steel structure series

Screw Elevator

Vertical Elevator

-

Software Center

more

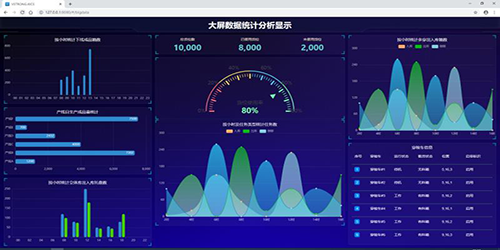

moreWQZN-WCS V4.0 is an open platform.We have successfully integrated with well-known WMS software and logistics subsystems.

more

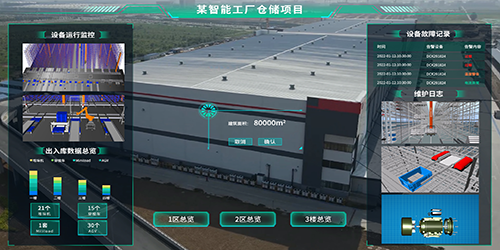

moreCombining users' deep business logic with 3D visualization technology to digitally model the real world

more

moreAutoWMS system is one of Vstrong's core software products, which is mainly targeting the pharmaceutical distribution industry.

-

Industry Solutions

Medicine E-commerce Semiconductor Beauty Makeup Photovoltaic Manufacture Third Party Logistics Cold Chain Shoes and Clothing

more

moreWe provide personalized solutions for different scenarios to help enterprises build modern pharmaceutical logistics centers with high automation, intelligence, efficiency, and standards.

more

moreWe provide you with a one-stop e-commerce full chain logistics solution, which improves the flexible design of the logistics center, the speed and accuracy of order fulfillment, and the order completion speed of automated systems can be N times faster than manual systems…

more

moreThe order-based production characteristics of semiconductor equipment have put forward higher requirements for production logistics and distribution. The logistics center needs to prepare materials according to orders and ensure that they can quickly respond to production rhythms and supply them to the production line in a timely manner.

more

moreTailored to create a first-class modern logistics center for beauty companies, to solve the supply chain operation, sorting, logistics and other problems caused by their rapidly growing sales volume

more

moreTo provide you with a comprehensive solution for photovoltaic energy, achieving flexible handling and meeting the needs of human-machine mixed driving scenarios; Greatly reduce manpower investment, reduce development difficulty, and improve overall operational efficiency.

more

moreWe provide you with a one-stop digital intelligent solution for the manufacturing industry, reducing storage space usage to free up capacity, shorten process time, reduce interruption risk, and improve security, while reducing production and distribution costs.

more

moreWe provide you with 3PL industry solutions that can simultaneously serve multiple users and maximize resource utilization, greatly improving inventory turnover and operational efficiency, as well as order fulfillment speed and accuracy.

more

moreAccelerated food circulation, ensured continuous temperature conditions in the cold chain, and ensured food safety; The application of automated unmanned three-dimensional warehouses also ensures the safety, environmental protection, and efficiency of food storage and retrieval.

more

moreTo provide you with shoe and clothing solutions suitable for diverse customer needs, greatly improving inventory turnover and operational efficiency, as well as order fulfillment speed and accuracy

-

After-Sale Service

7 * 24-hour technical support A comprehensive spare parts management system A nationwide after-sales service system

more

moreAccording to user requirements and maintenance needs, we prepare a spare parts plan to ensure the normal operation of maintenance work.

-

News Center

-

About Us

more

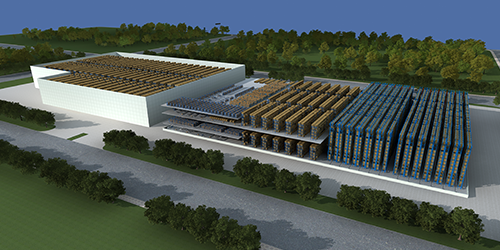

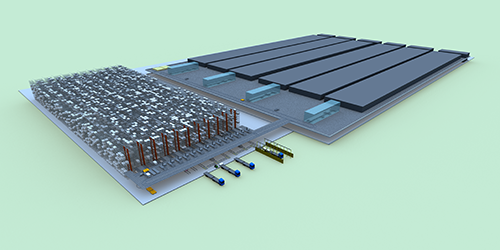

moreBeijing VSTRONG Technology Co., Ltd. is a well-known logistics system integrator in China, providing customers with professional solutions for modern logistics systems.

more

moreboth parties have reached a close partnership to jointly promote the new development of China's logistics industry.

more

moreBeijing VSTRONG Technology Co., Ltd. is a well-known logistics system integrator in China, providing customers with professional solutions for modern logistics systems.

Collect us